Improving The Efficiency Of Green Technologies

& Biofuels Using Elemental Analysis

Customers in the biofuels and greener technology sectors are benefitting from RTI – Real Time Instrument’s ability to take developments in moisture analysis and elemental analysis in the coal and resources sector and apply them to the analysis and identification of mineral matter and dirt.

What are the value benefits of Real Time Instruments

One such proven application is in the sugar cane industry, where RTI’s GammaScan was used to effectively measure mud/dirt levels in on-conveyor cane billets being fed into a Queensland Sugar Mill. Because dirt is a more radioactive material than sugar cane, the GammaScan technology enabled mill and feed operators to identify when dirt levels became too high and take preventative action against mill breakdown and inefficiencies in processing.

The ability to measure dirt and mineral matter in a biofuel / green technology process is critical in ensuring the process is as efficient and clean as possible. A similar principle applies to moisture, which is why RTI’s MoistScan has also proven its worth in this space. By giving operators visibility and control over moisture levels in everything from biomass to pulp, woodchip and other alternative energy sources, contingent actions can be taken to manage raw materials being fed into the processing system to ensure energy is not wasted in the burning or processing of those materials. This means a more efficient process, cleaner and more effective energy use and that leads to reduced costs and maximum yield.

Read how RTI has saved its customers time and money in this sector by downloading our case studies!

Integrated Solutions

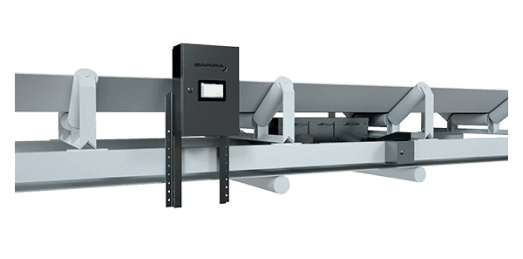

Advanced moisture measurement solution for any bulk material transported on conveyors

GammaScan

Where a radiation source is not an option, the GammaScan is that solution.

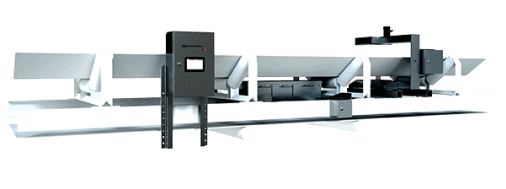

GammaScan – DUO

Where a radiation source is not an option, the GammaScan is that solution.