AllScan, GammaScan & MoistScan Technology - Delivering Improved Metallurgical Solutions

RTI Real Time Instruments is working with some of the world’s leading critical minerals operations, flexing its already-proven technology to deliver efficiencies, cost savings and cleaner processes across commodities including Copper, Iron Ore, Nickel, Bauxite and Manganese.

What are the value benefits of Real Time Instruments

Through moisture analysis and elemental analysis, RTI works with customers, using our AllScan, GammaScan and MoistScan technology, to deliver solutions around stockpile management, ore sorting and grade control, and working to achieve maximum efficiency and productivity across mining and processing operations. Our analysers give full visibility over ore throughput – and enable decisions to be made to achieve maximum economic viability in mining and processing – with real-time, on-line, high-fidelity data at an operator’s fingertips, to enable immediate decisions when it is most important.

We are also working with our customers in developing tailings solutions to better manage and control waste while ensuring no vital ore is wasted. Similarly, where there are secondary resources and elements present, we can work with customers to give them complete visibility over this and ensure a greater level of control over the mining, processing and management – and ultimately the sustainability – of the ore body. Rogue element identification is also important, and working with customers, RTI’s technology has enabled visibility – and subsequent action – not just over those elements which are meant to be there, but also over those that are not wanted.

It’s this level of visibility and control that enables operators to make intelligent decisions in real time to recover more and waste less.

Read how RTI has saved its customers time and money in this sector by downloading our case studies!

Integrated Solutions

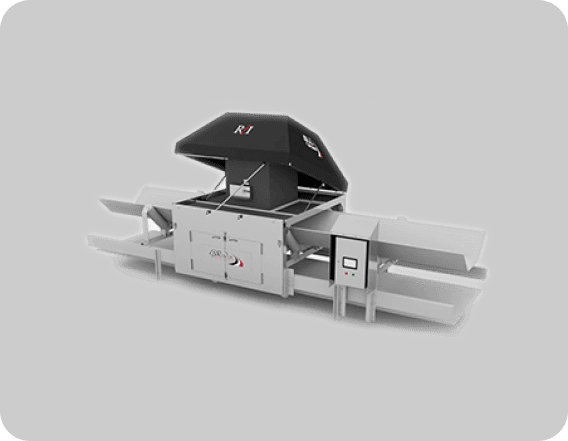

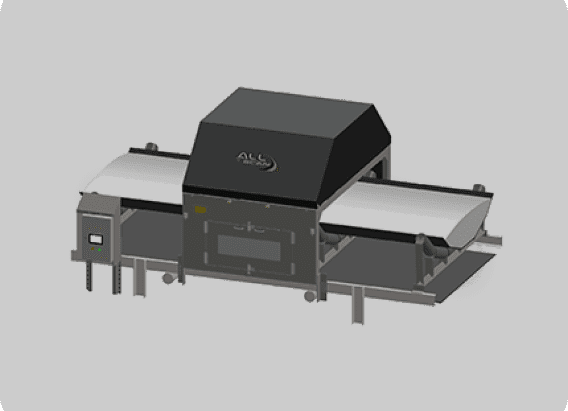

AllScan n-Gen

The smartest neutron generation elemental analyser in the world

AshScan

Designed to be practical, the AshScan is simple to install, set-up and calibrate.

AshScan – DUO

Designed to be practical, the AshScan is simple to install, set-up and calibrate.

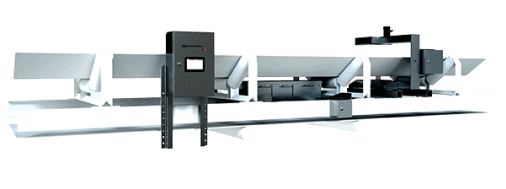

Advanced moisture measurement solution for any bulk material transported on conveyors

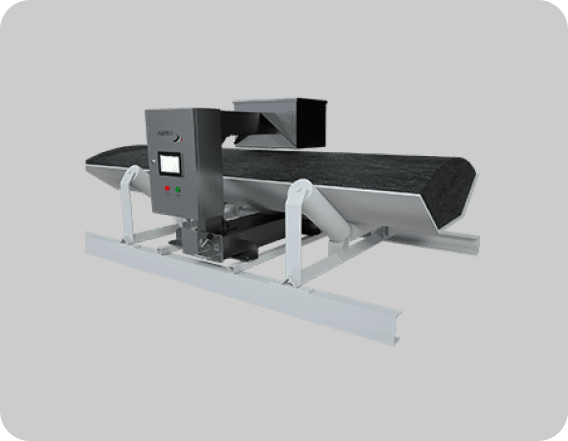

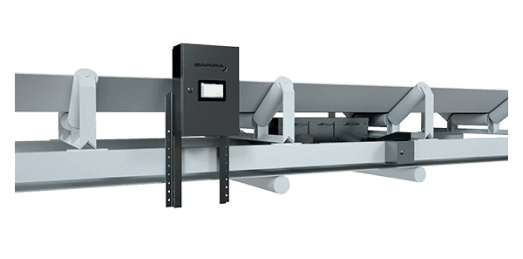

GammaScan

Where a radiation source is not an option, the GammaScan is that solution.

GammaScan – DUO

Where a radiation source is not an option, the GammaScan is that solution.