Using Elemental & Moisture Analysers In Steel Production To Maximise Productivity

Understanding the elemental composition and moisture content of the material you are feeding into your steel production processes is vital to maximising efficiencies and minimising costs. It’s here that RTI – Real Time Instruments’ suite of elemental and moisture analysers have proven vital across in-feed, stockpiling and ore blending to assure grade control. Across the steel production industry, RTI’s analysers have filled a critical niche in identifying and enabling the control of rogue elements, building stockpiles that meet precise specifications and minimising waste.

What are the value benefits of Real Time Instruments

While financial and lost-productivity costs are minimised as a result of operators having full visibility and real-time, in-situ control of highest-grade ore being fed into production plants, RTI’s elemental and moisture analysers also enable sites to optimise energy consumption – and reduce emissions – because of the higher integrity of coal being fed into the plant.

RTI’s elemental analysers – including our AllScan range – are also central to an operation’s ability to monitor the presence of elements such as aluminium, silicon, magnesium, phosphorous and potential rogue elements in iron ore, in stockpiling to enable blending and ore grade control ahead of the sintering process. Such analysis can also be calibrated to target precise amounts of specific elements within the ore’s composition.

In addition to the production process, the compositional analysis of waste and slag is also being researched by RTI’s team, in concert with customers eager to reduce their waste and maximise the use of materials.

Read how RTI has saved its customers time and money in this sector by downloading our case studies!

Integrated Solutions

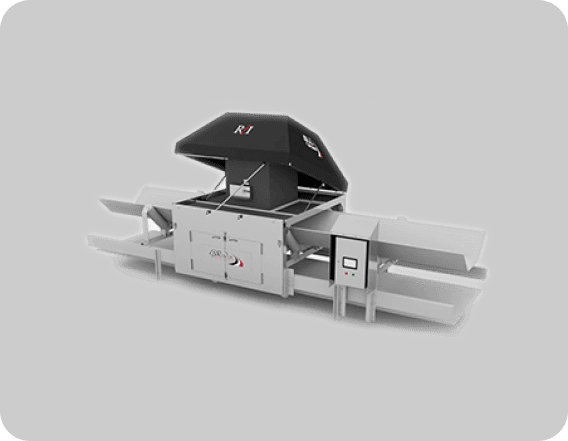

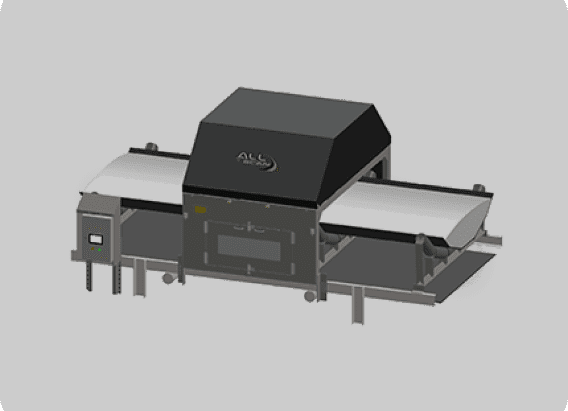

AllScan n-Gen

The smartest neutron generation elemental analyser in the world

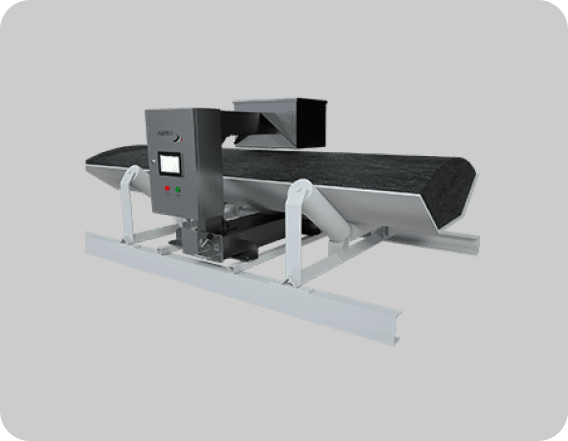

AshScan

Designed to be practical, the AshScan is simple to install, set-up and calibrate.

AshScan – DUO

Designed to be practical, the AshScan is simple to install, set-up and calibrate.

Advanced moisture measurement solution for any bulk material transported on conveyors