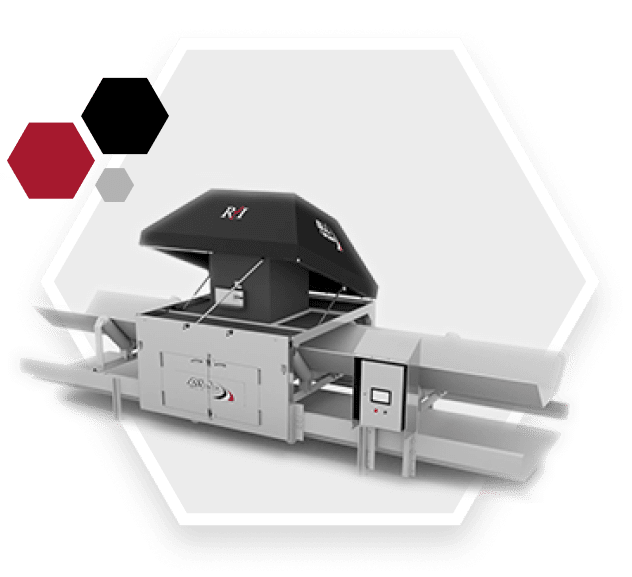

AllScan Cf-252

Steel Production

The AllScan CF-252 PGNAA analyser combines state-of-the-art technology with ground-breaking spectra modelling and powerful statistical analysis in provision of elemental analysis in real time. Installed on a conveyor belt, the AllScan delivers accurate, minute-by-minute elemental analysis and reporting of the chemical composition of bulk materials and key process parameters.

AllScan Steel Production Analyser

Accurate real time data on the composition of raw material feed streams before stockpiles or sinter oven, increases product quality and contributes significantly to reduced production costs. Since its market introduction in the 1980s PGNA Analysis is widely acknowledged as the by far superior on-line analysis technology for steel production process quality optimization. Documented by close to 100 installations, the documented analytical performance coupled with the very fast control response means that PGNAA has grown to become the leading on-line quality control concept in the steel production industry.

Other on-line analysis technologies applied in steel production, such as IR/NIR/-FTIR and XRF/EDXRF analyses the material/sample surface only, while the penetrating concept of PGNAA measures the entire product stream. RTI’s AllScan analyser has been developed with particular emphasis to address practical analytical challenges experienced with less advanced analysers. Best in class robustness of the applied calibration model as well as high tolerance towards material depth variations and effects from layering on the belt conveyor through the analyser are some of the most notable benefits of AllScan. Very low installation costs and moisture analysis capability always included with no added costs makes the Total Cost of Ownership (TCO) for a typical steel production installation the lowest on the market.

Theory of Operation

At the heart of the AllScan is PGNAA – prompt gamma neutron activation analysis. Material on the conveyor is bombarded with neutrons emitted from radioactive isotope.

When neutrons collide with an element in the material, gamma rays are emitted with a specific energy unique to that element – in effect, creating chemical signature for that element. The greater the amount of an element in the material the greater the number of gamma rays emitted with the corresponding specific energy. By measuring the specific energy of the gamma rays that are emitted and the counts of gamma rays, an accurate analysis of the chemistry of the material is generated on a second-by-second basis.

AllScan Benefits and Measurement Parameters for the Steel Production Industry

The AllScan can be applied to measure the quality of the incoming raw materials to enable operators to produce pre-blended stockpiles based on preferred parameters such as Fe, Mg, Si, Ca etc content. The pro-active control of pre-blending result in a more consistent quality product delivery into downstream processes like sinter and coke production, blast furnace feed and ultimately the final product delivery. Parameters such as:

Basicity (Ca/Si) can be controlled to produce higher throughput rates in the sintering process, increase burn through and reduce the amount of fines requiring additional processing and associated costs. The basicity of sinter material is an important parameter to ensure the efficient operation of the sintering and ultimately iron production process. The AllSan for sinter measure the sinter feed chemistry in real time and provide minute by minute data to enable pro-active control of the basicity. With additional control software the process of basicity correction can be done automatically resulting in a more consistent sinter product with reduced fines and increased sinter oven throughput.

The measurement of important elements like:

- Silver (Ag)

- Aluminium (Ag)

- Gold (Au)

- Calcium (Ca)

- Cadmium (Cd)

- Chlorine (Cl)

- Cobolt (Co)

- Chromium (Cr)

- Copper (Cu)

- Iron (Fe)

- Magnesium (Mn)

- Sodium (Na)

- Nickel (Ni)

- Phosperous (P)

- Sulphur (S)

- Silicon (Si)

- Titanium (Ti)

- Vanadium (V)

- Zinc (Z)

provide operators with real time data on elemental concentration levels to increase efficiency, reduce operating costs and ultimately improve bottom line profitability.