Using Moisture & Elemental Analysis in Cement Processing

RTI’s Cement customers rely on our ability to provide on-line, real-time, highest-fidelity data around the composition and grade of materials. As such as highly-engineered product, cement is produced within stringent parameters. RTI’s moisture analysis and elemental analysis technology, namely our AllScan and MoistScan analysers, enables full, to-the-minute visibility over the precise blend of materials.

What are the value benefits of Real Time Instruments

With the capacity to identify, analyse and measure the composition of more than 60 elements, the concentration of materials, such as silicon, iron and aluminium, can be traced, and ore blending and sorting adjusted as soon as a deviation from the specification is noticed. The RTI technology is also effective in rogue element detection, identifying too high or too low levels of elements that can compromise the integrity of the final product.

From stockpile management through to blending and re-blending, reclamation, and final output, RTI’s MoistScan, AllScan, n-Gen, and Slurry technology are critical in empowering cement operations with the visibility and control over their bulk material handling and processing. While the efficiencies are evident, this technology has been proven effective as part of integrated solutions to boost productivity, shore up product integrity, and save costs in minimising the production of sub-standard products while also having the ability to reclaim material that might otherwise have been wasted.

Read how RTI has saved its customers time and money in this sector by downloading our case studies!

Integrated Solutions

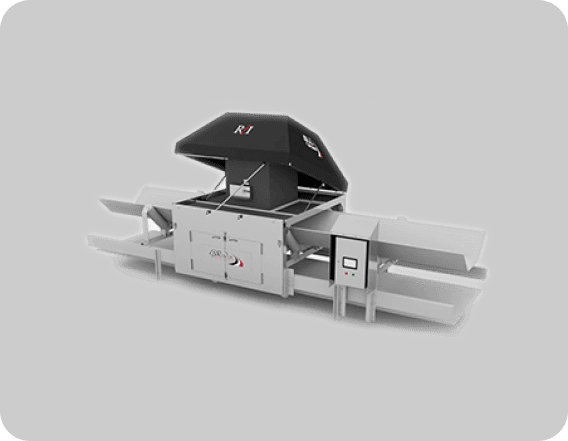

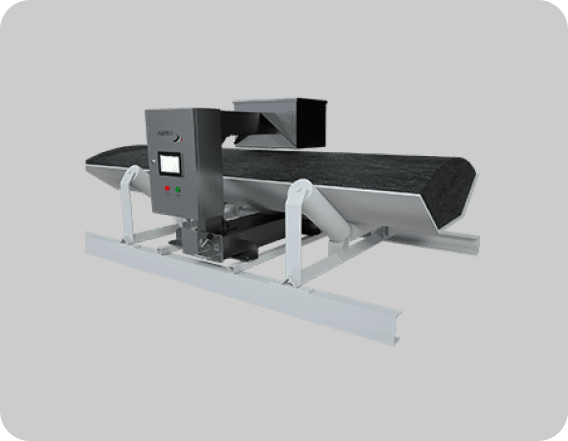

AllScan n-Gen

The smartest neutron generation elemental analyser in the world

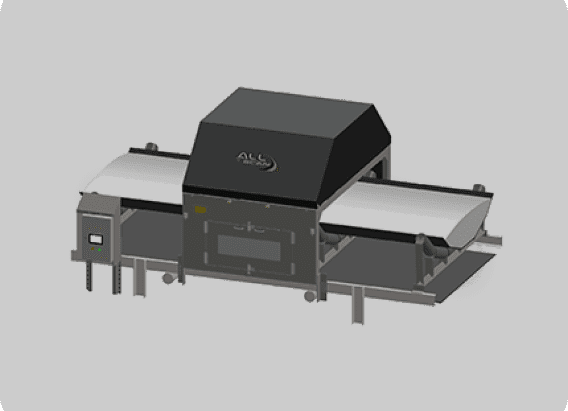

AshScan

Designed to be practical, the AshScan is simple to install, set-up and calibrate.

AshScan – DUO

Designed to be practical, the AshScan is simple to install, set-up and calibrate.

Advanced moisture measurement solution for any bulk material transported on conveyors