Allscan Slurry is an innovative on-line elemental analysis technology for mineral slurry processing

- Superior analytical performance

- Simplified calibration procedure

- Low cost of ownership

AllScan Slurry The World’s Most Advanced PGNAA Elemental Analyser

The AllScan slurry analyser is the new benchmark in online analysis of critical slurry streams in mineral and coal processing plants.

The system does not require the sampling systems normally associated with other available technologies on the market.

What is AllScan Slurry

Allscan Slurry On-line elemental analysis is used in a wide range of mineral processing applications throughout the supply chain, from extraction through to mineral manufacturing.

Smart Next Generation AllScan Slurry for Different Industry

AllScan Slurry On-line elemental analysis is used in a wide range of mineral processing applications throughout the supply chain, from extraction through to mineral manufacturing.

Select Industry

Most Advanced PGNAA Slurry Analyser

Dura-G™ – a Unique Analytical Calculation Concept

A well-known challenge with the PGNAA technology is deconvoluting the highly complex raw spectrum, which includes important elemental spectra and significant unwanted “noise/disturbance factors” from sample presentation, material density variations, surrounding structures, etc.

These “presentation effects” are often stronger than the “composition” effects. However, the Dura-G technology built into AllScan smartly separates these effects, i.e., it allows for all of the spectral components of the complex Prompt Gamma spectrum to be correctly allocated to Compositional or Presentation effects.

Thus, by the removal of the “noise components” from the complex raw Prompt Gamma spectrum, Dura-G creates a cleaned-up range, which:

- increases the signal-to-noise ratio of the measured compositional signal and improves the de-convolution of the same to provide output data with reduced measurement error compared to the traditional raw spectrum

- Supports a sophisticated calibration sample-free calibration methodology to provide an elemental analyser that is not dependent on material or ongoing calibration techniques.

The Dura-G analytical calculation techniques employ advanced mathematical tools that have not previously been used in PGNA gamma spectrum analysis. The AllScan and its innovative calculation scheme were developed in cooperation with the University of North Carolina (USA) and other world-leading radiation experts.

Dura-G is a unique modelling and calculation concept based on sophisticated algorithms that separate the effect of environment and process variations on the measured spectra from the impact of elemental variations. In the processing, the significant noise attributable to hydrogen is also eliminated.

Features & Benefits of our world-first Neutron Generation Analyser

-

Higher performance on-line, real-time results

Accurate minute-by-minute results for multiple flow rates. Advanced PGNAA design and Dura-G technology significantly improve the performance of full elemental analysis (Fe, Al, Si, K, S, Ti, Ca, etc.).

-

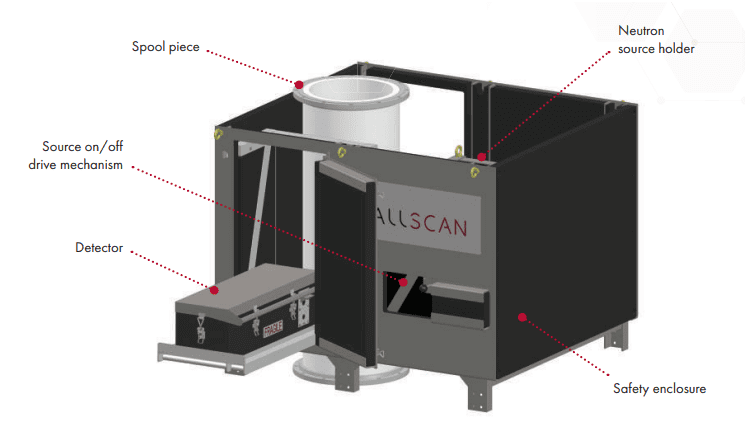

Safety

Through improved design, AllScan slurry employs a minor source, reducing the required shielding and overall cost of life of the analyser. Personnel can safely work next to the analyser without using toxic lead shields, making it the lightest PGNAA slurry on the market.

-

Rugged and reliable

Like all RTI elemental analysers and gauges, the AllScan slurry has been purpose-designed to work in harsh mine environments—100% constructed from corrosion-free materials, i.e. stainless steel.

-

Easy to install

AllScan Slurry is considerably lighter than conventional elemental analysers and bolts onto most pipes without alterations or foundations required—only five days for complete installation, commissioning and calibration.

-

Low running costs

All military spec. Components used in the slurry analyser eliminate the need for an air-conditioner and associated ongoing maintenance in hot environments.

-

Easy operation

User-friendly colour touch screen with intuitive menus housed in an IP66 stainless steel control enclosure for field or remote mounting. Flexible I/O and multiple interface protocols are available to suit the client’s needs.

-

Remote access and back-up

Includes a 3G interface linked to a secure website for full remote diagnostics as standard—cloud-based back-up for safe archiving of essential data. Customised monthly operational, integrity and data reports are provided through remote access for support agreements.

-

Simple calibration verification

No more labour-intensive material sampling. The slurry elemental analyser accuracy is verified through calibration standards, enabling rapid checks and returning to production quickly. Dynamic sampling will align the analyser with laboratory results.

Economic Benefits of the AllScan Slurry

Utilising available seamless interface options, users of AllScan can access composition analysis of slurries on a minute-by-minute basis, rolling average and interval basis. Pending the specific application details, some or all of these operational benefits will be experienced:

- Complete stream analysis reducing the effect of sampling bias

- Direct on-line analysis without sampling latency

- No moving parts are typically associated with other analysis methods

- Improved yield through proactive control of process additive consumption

- Reduction in waste management cost

- Small footprint and low mass with the decrease in structural steel requirements

Online PGNAA is suitable for coal and most mineral ores, including:

- Iron ore

- Bauxite

- Copper

- Manganese

- Phosphates

- Sulphide and Laterite Nickel Ores

- and more

Detectable and measurable elements include:

- Ag

- Cu

- Al

- Fe

- Au

- K

- Ca

- Mg

- Cd

- Mn

*Even difficult to measure elements, like Phosphorus.

Customer defined ratios can also be reported, for example, Al:Si, Ca:Mg and Ni:Fe.

Product Specification of our AllScan Slurry PGNAA Analyser

| Measurement Technique | Prompt Gamma Neutron Activation Analysis (PGNAA). |

| Analytical Data Reported | User defined. Most elements can be reported depending on concentration and accuracy required. Typical elements include Ag, Al, Au, Ca, Cd, Cl, Co, Cr, Cu, Fe, K, Mg, Mn, Na, Ni, P, S, Si, Ti, V, Zn, Moisture. User-defined modules can also be reported, e.g. Ca:Si, Si:Mg, Ni:Fe Optional trace elements include: Hg, As and Se |

| Weight | 850 – 1000kg depending on pipe diameter used. |

| Source | Standard analyser is loaded with 20µg Cf252 (2.6 years half-life). For larger pipes or high performance applications 40µg Cf252 is used. Typically, an initial 20µg Cf252 source is topped up with 10µg after 2.5 years and again after 5 years. Disposal occurs at 7.5 years. |

| Source Holder | Automatic source drive with automatic fail safe in event of power loss. Physical isolation point. Complies with all radiation safety requirements. |

| Radiation Exposure | Typically below 5µSv/hour outside and around the exterior of the analyser average 1.3µSv/hr on or near the catwalk beside the analyser. |

| Communications | At the analyser – 10” graphite LCD colour touchscreen local operator interface analyser to customer PLC System – Modbus over RS-485 (default standard). Most industrial communication protocols over Ethernet (TCP/IP), RS-485, RS422, RS-232. Facility for OPC client/server link

Remote Support – 3G wireless, built-in web server allows remote view or control from any internet connected PC, tablet or smart phone. |

| Operating Temperature | Sensitive parts of the AllScan are sealed from the environment. The analyser is designed to operate in all outdoor weather conditions from -20 to +50°C (14 – 122°F) in high or low humidity or precipitation. |

| Power Control | Instrument quality 120/240VAC; single phase; 300W; 50/60Hz; at analyser |

| Control Cabinet | IP66 rated, 316 stainless steel cabinet 800mm wide x 600mm high x 300mm deep (31in wide x 23in high x 12in deep). |

| Frame | Industrial-grade 316 stainless steel framing, Non-corrosive 316 stainless steel fasteners, High-grade HDPE shielding. |

| No Massflow meter required | The AllScan analyser does not require a massflow meter input to function. Proprietary technology makes the requirement for a flow rate input obsolete. |

Contact Real Time Instruments

For general enquiries or to see how we can enhance your business growth.