AshScan DUO Fossil

Fueled Power Generation

The AshScan DUO Low Energy Transmission (LET) analyser combines state-of-the-art nuclear and microwave technology with ground-breaking modelling and powerful statistical analysis. Installed on a conveyor belt, the AshScan delivers accurate, minute-by-minute data on percentage ash and moisture content present in the coal feed to the kiln. Combining the LET technology with microwave technology enable to measurement of both the ash content and moisture content in critical process streams to control drying process, improve the calcining and ultimately kiln efficiency in the production of clinker.

AshScan DUO in the Coal Fired Power Generation Industry

The AshScan Online Coal Analyzer provides realtime, continuous data on total ash and moisture content in coal. Using DUET (duel energy transmission) technology, also known as LET (low energy transmission) and low frequency microwave technology, the AshScan is a tried and proven performer suitable for most coal types.Ash consists mainly of oxides of Silicon (Si), Iron (Fe), Aluminium (Al) and Calcium (Ca). The AshScan measures the combined total of these elements which directly correlates to the total ash content in coal.The DUET technique uses two radioactive sources; Am-241 and Cs-137. Am-241 is a low energy gamma radiation. Absorption of Am-241 gamma rays occurs due to the presence of Si, Fe, Al and Ca, and the amount of coal on the conveyor. Cs-137 is a high energy gamma radiation. Absorption of Cs-137 gamma rays is due only to the amount of coal on the conveyor. This allows the Am-241 measurement to be normalised for bed depth. The normalised Am-241 absorption is then correlated to total Ash content by calibrating against laboratory reported ash sample results.The AshScan is suitable for both raw coal and washed coal where ash chemistry is relatively stable and where the bed depth of the coal does not exceed 350mm.Its practical design incorporates many unique features not available in other through belt ash gauges. The AshScan on-belt coal analyser’s modern electronics, communications and human machine interface makes set-up, calibration and ongoing verification of accuracy simple and straightforward.The AshScan is commonly used in the coal and power industries for:

- Monitoring and correction of received coal

- Stocpile building to a redetermined quality requirement

- Consistent quality feed to boiler bunkers

- Improved boiler operations

- Increased boiler efficiency

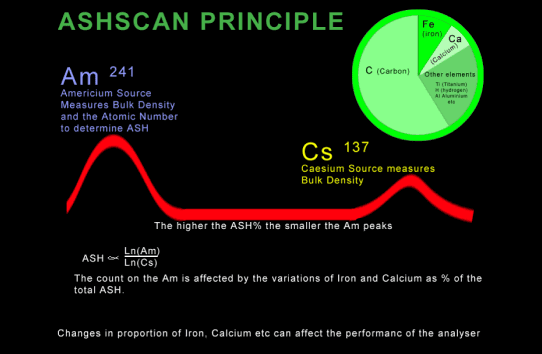

AshScan DUO operating principle.

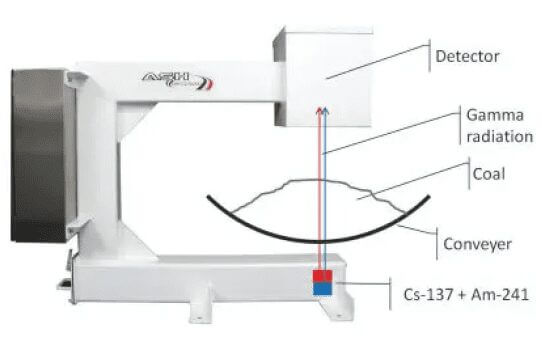

The AshScan utilises two radioactive sources. The technology is referred to as Dual Energy Transmission (DET) or Low Energy Transmission (LET).

LET analysers uses a Am-241 source which transmits “soft X-rays” at 60keV, which measures the density/atomic number of the ash forming elements within the coal. The higher the Ash content, the less 60keV rays will reach the detector. The second source Cs-137 transmits higher energy gamma rays at 660keV, which measures the bulk density of the coal and compensates for the bulk density and bed depth variations. If the Fe and Ca varies significantly within the coal, it will affect the accuracy of this analyser and introduce a shift in the calibration. E.g. wash plant receiving coal from 2 or 3 different mines with different Fe & Ca content. The analyser can store up to 16 different calibrations for different coal types, but it needs an input to know which coal is being feed at any given time, e.g. Coal from Mine A or B, etc. Accuracy is approx. 0.9 -1%

The AshScan has proprietary counting electronics, which is the fastest available on the market. The measurement and output has the fastest update time of less than 25 seconds.