Using AllScan, AshScan & MoistScan To Maintain Quality Coal Mining

Coal, by its nature, is dirty. From the moment it is dug out of the ground, right through until it reaches its end-user application, coal is one of the most controversial – yet vital –resources on the planet. Because it is vital, that when so many are running away from coal – be it thermal or metallurgical – RTI Real Time Instruments is running, at full speed toward it.

What are the value benefits of Real Time Instruments

Why? Well, for the past 20 years, our RTI team has been working with customers to develop world-leading technology which delivers up-to-the-minute, high-fidelity, in-situ visibility over the grade, calorific value, elemental composition (with our AllScan and AshScan analysers) and moisture content (with MoistScan), of coal at every stage of mining and processing. This technology means operators have a level of control over what’s on their conveyor belts that empowers them to blend, sort, dilute and stockpile to achieve the best possible product outcomes.

RTI’s elemental analysers, ash analysers, and moisture analysers are relied upon by some of the world’s biggest miners – as well as juniors and start-ups – to enable a level of control that has led to operational productivity improvements of up to 5% in some cases. This translates into millions of dollars in saved penalties and means specification deviations can be mitigated in real time – instead of waiting several hours, or longer, for lab results; by which time, the coal is en route to the customer.

RTI’s elemental and moisture analysers have broad applications across the full spectrum of mining processes – from the pit to the wash plant (or even by-passing the wash plant where it is possible), to the port to the end user. RTI gives customers complete control and understanding of precisely what’s leaving their minds and being shipped to market.

Read how RTI has saved its customers time and money in this sector by downloading our case studies!

Integrated Solutions

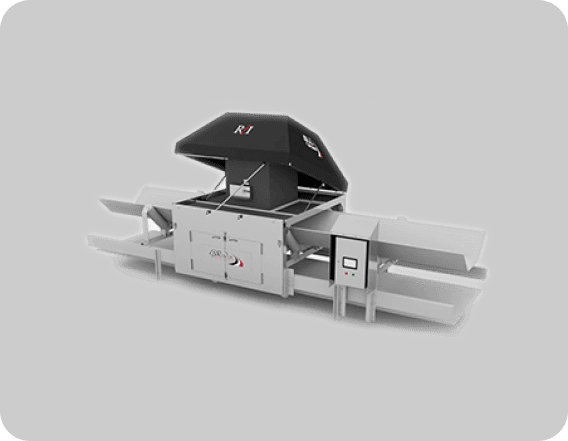

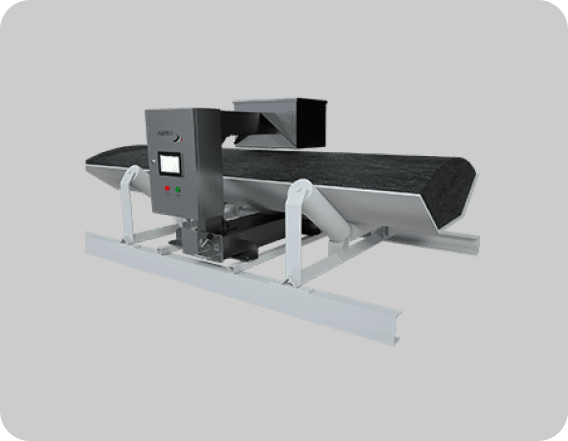

AllScan n-Gen

The smartest neutron generation elemental analyser in the world

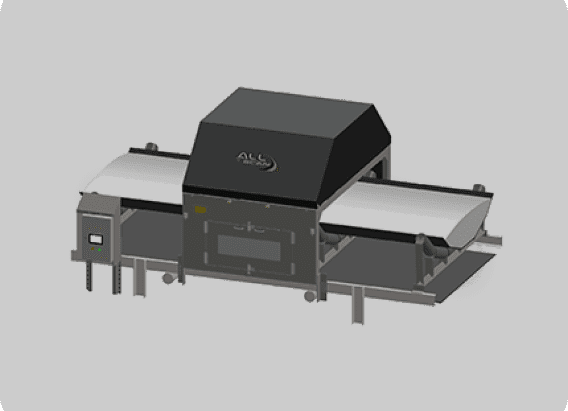

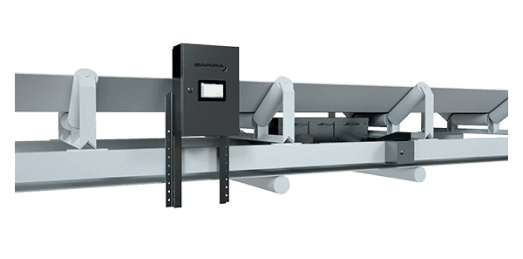

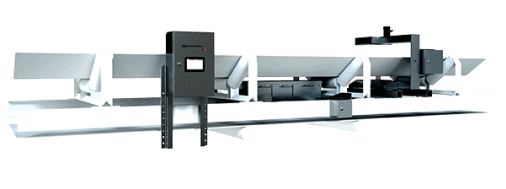

AshScan

Designed to be practical, the AshScan is simple to install, set-up and calibrate.

AshScan – DUO

Designed to be practical, the AshScan is simple to install, set-up and calibrate.

Advanced moisture measurement solution for any bulk material transported on conveyors

GammaScan

Where a radiation source is not an option, the GammaScan is that solution.

GammaScan – DUO

Where a radiation source is not an option, the GammaScan is that solution.