Allscan CF 252 is a quantum leap in PGNAA analyser technology, delivering higher yields, increased returns, and lower costs for your operation.

- World-best analyser innovation

- Simple, intuitive calibration

- Lowest cost of operation in the market

- Maximise output, minimise downtime and costs

AllScan CF-252 The Smartest PGNAA Elemental Analyser in the World

The AllScan brings together world-best innovation and the smartest technology to deliver the most advanced PGNAA elemental analysers in the world today.

The AllScan CF 252 utilises the well-established technique of PGNAA (Prompt Gamma Neutron Activation Analysis) which performs a direct measurement of elements such as Fe, Al, Si, K, S, Ti, Ca and many others.

The sensitivity varies depending on the element being measured, so some elements can be detected with greater sensitivity than others – for example iron (Fe), sulfur (S), calcium (Ca), mercury (Hg) and titanium (Ti) are all especially sensitive.

What is AllScan CF-252

The AllScan CF 252 is the world’s most advanced PGNAA analyser. It is well suited to a broad spectrum of ore and material types, from high/variable ash feed, to low ash product.

Next Generation AllScan Cf-252 for Different Industry

AllScan PGNAA On-line elemental analysis is well suited to a broad spectrum of ore and material types, from high/variable ash feed, to low ash product.

Select Industry

Features & Benefits of our Smart Next Generation PGNAA Slurry Elemental Analyser

-

Higher performance on-line, real-time results

Accurate minute-by-minute results for multiple flow rates. Advanced CF-252 PGNAA design and Dura-G technology allow significant improvement in the performance of full elemental analysis (Fe, Al, Si, K, S, Ti, Ca, etc.) as well as moisture, offering superior performance over a much more comprehensive range of bed depths than similar analysers.

-

Safety

Through improved design, AllScan CF-252 employs a minor source, reducing the required shielding and overall cost of life of the analyser. Personnel can safely work next to the analyser without using toxic lead shields, making it the lightest PGNAA analyser on the market.

-

Rugged and reliable

Like all RTI elemental analysers and gauges, the AllScan CF-252 has been designed to work in harsh mine environments. 100% constructed from corrosion-free materials, i.e. stainless steel.

-

Easy to install

AllScan CF-252 is considerably lighter than conventional elemental analysers and bolts onto most conveyor structures without alterations or foundations required—only 5 days for complete installation, commissioning and calibration.

-

No belt weigher required

With the advanced analysis techniques the analyser employs, the AllScan Cf-252 does not require a belt scale input.

-

Low running costs

All military spec. Components used in the elemental analyser, eliminate the need for an air-conditioner and associated ongoing maintenance in hot environments.

-

Easy operation

User-friendly colour touch screen with intuitive menus housed in an IP66 stainless steel control enclosure for field or remote mounting. Flexible I/O and multiple interface protocols are available to suit the client’s needs.

-

Remote access and back-up

Includes a 4G interface linked to a secure website for full remote diagnostics as standard—cloud based back-up for safe archiving of essential data. Customised monthly operational, integrity and data reports are provided through remote access for support agreements.

-

Simple calibration verification

No more labour-intensive material sampling. The PGNAA analyser accuracy is verified through calibration standards, enabling rapid checks and returning to production quickly. Dynamic sampling will align the elemental analyser with laboratory results.

-

Unaffected by “high noise elements”

The only PGNAA analyser that maintains accuracy even on steel cord belts and fire retardant belts containing chlorine.

Most Advanced PGNAA Elemental Analyser

-

INSTALLATION

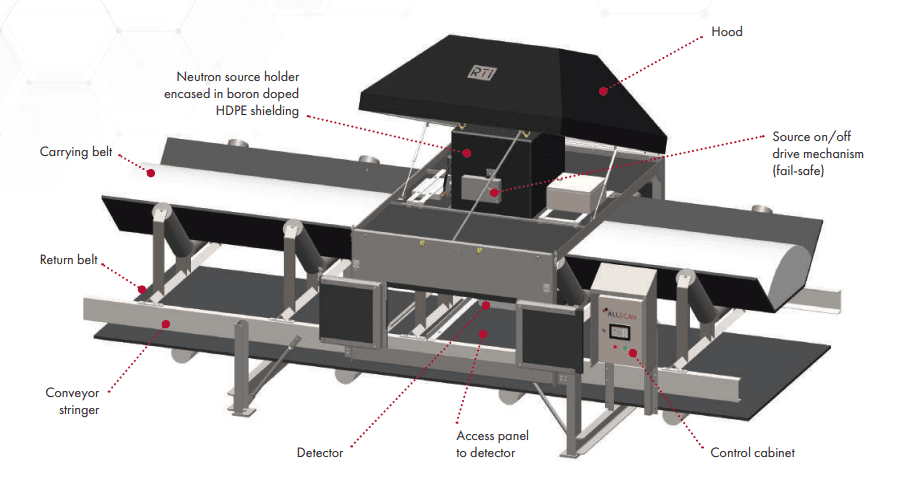

The AllScan Cf-252 is designed to be mounted on the support rails of a conveyor system and consists of four main sections:

- Two side assemblies.

- The top with source assembly.

- The detector box that mounts between the conveyor and return belts.

Individually, each section can be lifted into place by a crane. The small size and weight of AllScan Cf-252 dramatically simplifies installation, as it can fit onto most conveyor structures without any alteration. In addition, there is minimal intrusion onto walkways.

-

I/O AND DIAGNOSTICS

The AllScan comes with a browser-based touch panel interface in the control cabinet, allowing immediate access to all data and functions, including trending displays.

Various interface protocols are available, and the system can be set up to suit user requirements. Options include:

- PLC Interface

- Ethernet

- Serial communications such as Modbus

- 4 – 20mA

- Complicated wiring between the analyser and the control centre is eliminated.

In addition, a 4G interface is also included to upload data to a secure site automatically. This provides an alternative way to view and retrieve data completely independent of site communication infrastructure, providing a backup in case of site communications issues and allowing simple remote monitoring over the internet. It dramatically assists fast remote diagnostics and troubleshooting by RTI engineers.

Data is downloaded daily to compile reports sent to the user every month. The report includes system diagnostics, a secure software backup, and calibration for rapid system recovery in the unlikely event of failure.

All diagnostics are performed by the onboard computer, which provides continuous verification of the detector and electronics and validation of the status of components in the computer. This information is accessible to RTI engineers remotely via the internet through the 4G interface. The analyser can also automatically email the AllScan support team to report errors/faults.

Product Specification of our AllScan Cf-252 PGNAA Analyser

| Measurement Technique | Prompt Gamma Neutron Activation Analysis (PGNAA). |

| Elements Measured | Fe, Al, Si, K, S, Ti, Ca and others. Total Ash calculated using elements found in ash. |

| Moisture and BTU | Included as standard. |

| Weight | 1200 – 1500kg typical. |

| Belt Widths | 750 – 2400mm (30 – 96 inch). |

| Aperture | Variable; height of the tunnel should be sufficient to clear the material that flows through it so the analyser does not sustain damage from materials on the belt. AllScan analysers can be easily adjusted for the appropriate tunnel height during manufacture and installation. Customer should provide means of preventing large rocks from striking the analyser |

| Source | 20µg Cf-252 (2.6 years half-life). Source is topped up with 10µg after 2.5 years and again after 5 years. Disposal occurs at 7.5 years |

| Source Holder | Automatic Source Drive with automatic fail safe in event of power loss, Physical Isolation Point, complies with all radiation safety requirements. |

| Radiation Exposure | Typically below 5µSv/hour outside and around the exterior of the analyser. Average 1.3µSv/hr on or near the catwalk beside the analyser. |

| I/O Protocols Available | Sensitive parts of the AllScan are sealed from the environment. The analyser is designed to operate in all outdoor weather conditions from -10 to +50 degrees Celsius in high or low humidity or precipitation. |

| Environmental Conditions | Industrial-grade 316 stainless steel framing, Non-corrosive 316 stainless steel fasteners, High-grade HDPE shielding. |

| Power | Instrument quality 120/240VAC 1Ø 300W 50/60Hz at analyser control station. |

| Control Cabinet | Stainless steel IP66 as standard. |

| Frame | All framing members and fasteners are stainless steel. |

| No Belt Weigher Required | The AllScan analyser does not require a belt scale input to function. Proprietary technology makes the requirement for a feed rate input obsolete. |

Contact Real Time Instruments

For general enquiries or to see how we can enhance your business growth.