The Global leader in elemental analysis. AllScan N-Gen high-performance Elemental Analyser combines rugged construction with the most recent advances in PGNAA technology.

AllScan N-Gen the Smartest Neutron Generation Elemental Analyser in the World

The AllScan N-Gen analyser revolutionises elemental analysis with its pioneering neutron generation technology, advanced spectra modelling, and robust statistical analysis capabilities. This cutting-edge technology is a game-changer in the field, delivering unparalleled accuracy in real-time elemental analysis and comprehensive reporting of chemical composition and critical process parameters for bulk materials.

Installed seamlessly on conveyor belts, the AllScan N-Gen provides precise minute-by-minute analysis, ensuring quality control and optimisation. Its versatility knows no bounds, making it an indispensable tool for industries such as Cement Production, Coal Processing, Steel Production, and many more.

The AllScan N-Gen has become the trusted choice across diverse sectors thanks to its ability to enhance productivity, quality assurance, and process efficiency in various applications. Discover the transformative power of AllScan N-Gen and stay ahead in your industry.

What is AllScan n-Gen

AllScan n-Gen uses a long-life deuterium-deuterium fusion-based electrical neutron generator. It uses world-first neutron generation technology with ground-breaking spectra modelling and robust statistical analysis to provide elemental analysis in real time.

AllScan Neutron Generation for Different Industry

AllScan N-Gen is a quantum leap in analyser technology, delivering higher yields, increased returns, and lower costs for your operation. It is well suited to various ore types, from high/variable ash feed to low ash products.

Select Industry

Neutron Generation Dura-G Technology

The AllScan n-Gen utilises Neutron Generation (n-Gen) technology, which directly measures elements such as Fe, Al, Si, K, S, Ti, Ca and many others.

The sensitivity of n-Gen varies depending on the element being measured, so some elements can be detected with greater sensitivity than others – for example, iron (Fe), sulphur (S), calcium (Ca), mercury (Hg), and titanium (Ti) are all especially sensitive.

Conventional analysers are sensitive to chlorine. However, with the AllScan n-Gen Dura-G technology, RTI can be measured on high chlorine belts without the usual adverse effect on the analytical performance.

Features & Benefits of our world-first Neutron Generation Analyser

-

Higher performance on-line, real-time results

Accurate minute-by-minute results for multiple flow rates. Advanced n-Gen design and Dura-G technology significantly improve the performance of complete elemental analysis (Fe, Al, Si, K, S, Ti, Ca, etc.) and moisture, offering superior performance over a much more comprehensive range of bed depths than similar analysers.

-

Safety

Through improved design, AllScan n-Gen can employ smaller sources, thus reducing dose rates and permitting operators to safely stand next to or near the analyser and work safely near the entrance or exit of the conveyor with minimal exposure.

The source is contained in a fireproof and drop-tested housing and has an automatic fail-safe as standard. The source can also be switched off from the walkway (even while the conveyor is running) to reduce exposure so that maintenance can be undertaken in and around the analyser.

-

Rugged and reliable

Like all RTI elemental analysers and gauges, the AllScan n-Gen has been designed to work in harsh mine environments—100% constructed from corrosion-free materials, i.e. stainless steel.

-

Easy to install

AllScan n-Gen is considerably lighter than conventional elemental analysers and bolts onto most conveyor structures without alterations or foundations required—only five days for complete installation, commissioning and calibration.

-

Low running costs

All military spec. Components used in the analyser eliminate the need for an air-conditioner and associated ongoing maintenance in hot environments.

-

Easy operation

User-friendly colour touch screen with intuitive menus housed in an IP66 stainless steel control enclosure for field or remote mounting. Flexible I/O and multiple interface protocols are available to suit the client’s needs.

-

Remote access and back-up

Includes a 3G/4G interface linked to a secure website for full remote diagnostics as standard—cloud-based back-up for safe archiving of essential data. Customised monthly operational, integrity and data reports are provided through remote access for support agreements.

-

No belt weigher required

With the advanced analysis techniques the analyser employs, the AllScan n-Gen does not require a belt scale input.

-

Simple calibration verification

No more labour-intensive material sampling. The analyser accuracy is verified through calibration standards, enabling rapid checks and returning to production quickly. Dynamic sampling will align the analyser with laboratory results.

Why Real Time Instruments AllScan N-GEN?

At the heart of the AllScan is Neutron Generation (n-Gen) technology. Material on the conveyor is bombarded with neutrons emitted from radioactive isotopes or a neutron accelerator. RTI has incorporated a revolutionary new long-life neutron generator design into the AllScan n-Gen elemental analyser.

AllScan n-Gen incorporates a sophisticated algorithm – DuraG™ – that separates the effect of belt loading and profile variation on the measured spectra from the impact of elemental variation on the elemental spectra. DuraG™ dramatically reduces measurement error.

AllScan n-Gen also includes – DuraSum – a robust algorithm that eliminates the need for time-based data averaging to obtain stable results. This means that significant changes in elemental composition are reported almost instantaneously rather than minutes later. This, in turn, allows for rapid operational control. These breakthrough technologies combine with the reliability of the n-Gen measurement technique to deliver the most accurate and responsive coal elemental analyser on the market today.

The new cutting-edge design eliminates the need for Air-conditioners to cool the electronics. The AllScan package is provided in a small footprint, is fully contained and is the smallest n-Gen on the market. The AllScan n-Gen has an intrinsically safe auto-source on/off source mechanism.

The generator’s life span is more than ten years. There is a constant output of neutrons, with no decay over time, as with Cf-252 sources.

-

INSTALLATION

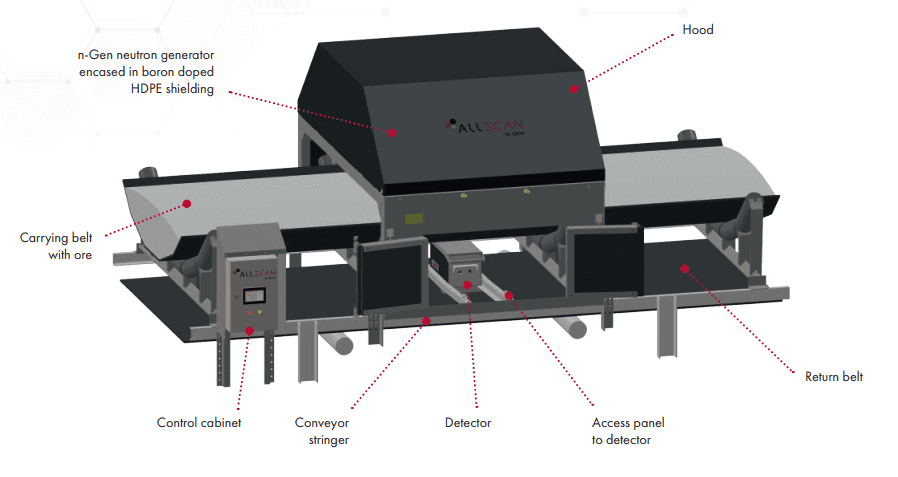

The AllScan n-Gen is designed to be mounted on the support rails of a conveyor system and consists of four main sections:

- Two side assemblies.

- The top with source assembly.

- The detector box that mounts between the conveyor and return belts.

Individually, each section can be lifted into place by a crane. The small size and weight of AllScan n-Gen dramatically simplify installation as it can fit onto most conveyor structures without any alteration. In addition, there is minimal intrusion onto walkways.

-

MAINTENANCE

The only maintenance requirement is that regassing is required every 2.5 – 3 years. When neutrons collide with an element in the material, gamma rays are emitted with a specific energy unique to that element, creating a chemical signature for that element. The greater the amount of an element in the material, the greater the number of gamma rays emitted with the corresponding specific energy. An accurate analysis of the material’s chemistry is generated on a second-by-second basis by measuring the particular energy of the emitted gamma rays and the counts of gamma rays.

Product Specification of our AllScan Neutron Generation Analyser

| Measurement Technique | Prompt Gamma Neutron Activation Analysis (N-Gen) |

| Elements Measured | Fe, Al, Si, K, S, Ti, Ca and others. Total Ash calculated using elements found in ash. |

| Moisture and BTU | Included as standard. |

| Weight | 1200 – 1500kg typical. |

| Belt Widths | 750 – 2400mm (30 – 96 inch). |

| Aperture | Variable height to suit material bed depth. The AllScan design incorporates adjustable mounting feet to accommodate future feed rate changes / increases. It is recommended that the client provide a means of preventing large rocks from striking the analyser. |

| Source | Deuterium-deuterium fusion-based neutron generator (20-40μg equivalent) producing low energy 2.45MeV neutrons. Deuterium fuel gas refilled on 2.5 – 3-year basis. |

| Radiation Exposure | Typically below 5µSv/hour outside and around the exterior of the analyser. Average 1.3µSv/hr on or near the catwalk beside the analyser. |

| I/O Protocols Available | Set up to suit application. Standard ModBus over RS485 and 3G/4G interface. User optional PLC Interface, ethernet, serial communications such as ModBus. |

| Environmental Conditions | Sensitive parts of the AllScan are sealed from the environment. The analyser is designed to operate in all outdoor weather conditions from -10 to +50 degrees Celsius in high or low humidity or precipitation. |

| Power | Instrument quality 120/240VAC 1Ø 300W 50/60Hz at analyser control station. |

| Control Cabinet | Stainless steel IP66 as standard. |

| Frame | All framing members and fasteners are stainless steel. |

| No Belt Weigher Required | The AllScan analyser does not require a belt scale input to function. Proprietary technology makes the requirement for a feed rate input obsolete. |

Contact Real Time Instruments

For general enquiries or to see how we can enhance your business growth.