Real Time Instruments

RTI is an Australian based company specialising in on-line elemental and moisture analysis of bulk materials providing operators with process data to make proactive real-time control decisions to improve plant efficiency and bottom-line profitability.

The Beginning

From our beginnings as an instrument service provider to the Australian coal industry, RTI has steadily grown and diversified into a high-tech manufacturer and supplier of on-line measurement and analysis equipment to the global mining, mineral processing, power generation, cement production and food industries. RTI’s customers range from small food processing facilities to large multinational mining and power generation companies on all continents.

With a vast global network of reputable business partners on all continents, we can provide customers with unmatched service and sales support ranging from on-site technical services to remote diagnostic and calibration expertise.

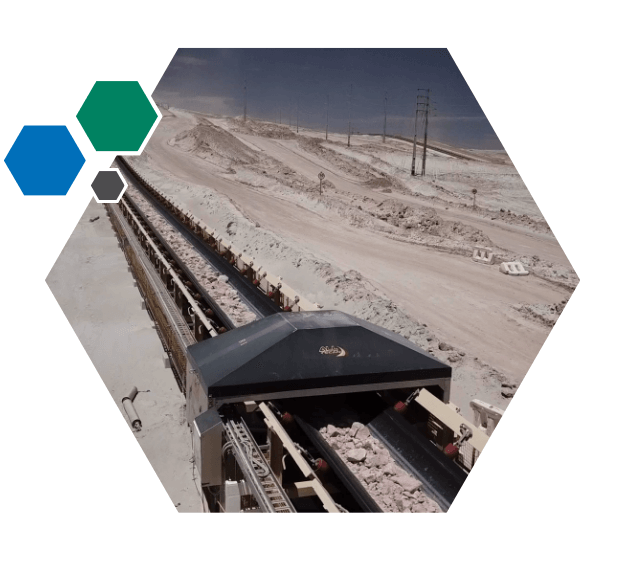

RTI’s on-line analysers utilise the latest technology to measure bulk material’s chemical composition, density, and moisture content as the product is transported on a conveyor belt. RTI’s ability to pivot its onshore manufacturing production line allows for easy customisation of existing products to facilitate the analysis of products in hoppers, screw-feeders, chutes, and pipes, in addition to standardised conveying systems.

Our Products

RTI's world-leading analysers equip our customers with powerful process analytics to assist in exceeding revenue, yield and production targets while reducing carbon footprint...

We help them reach Net-Zero targets through improved efficiency, tighter quality control and reduced emissions.

We collect and deliver on-line real time data to operators, meaning they can can make critical decisions - on the spot, when it matters.

Our product line includes Online Measurement, Analysis and Detection Equipment: